News + Updates

Find out what our team has been up to.

Find out what our team has been up to.

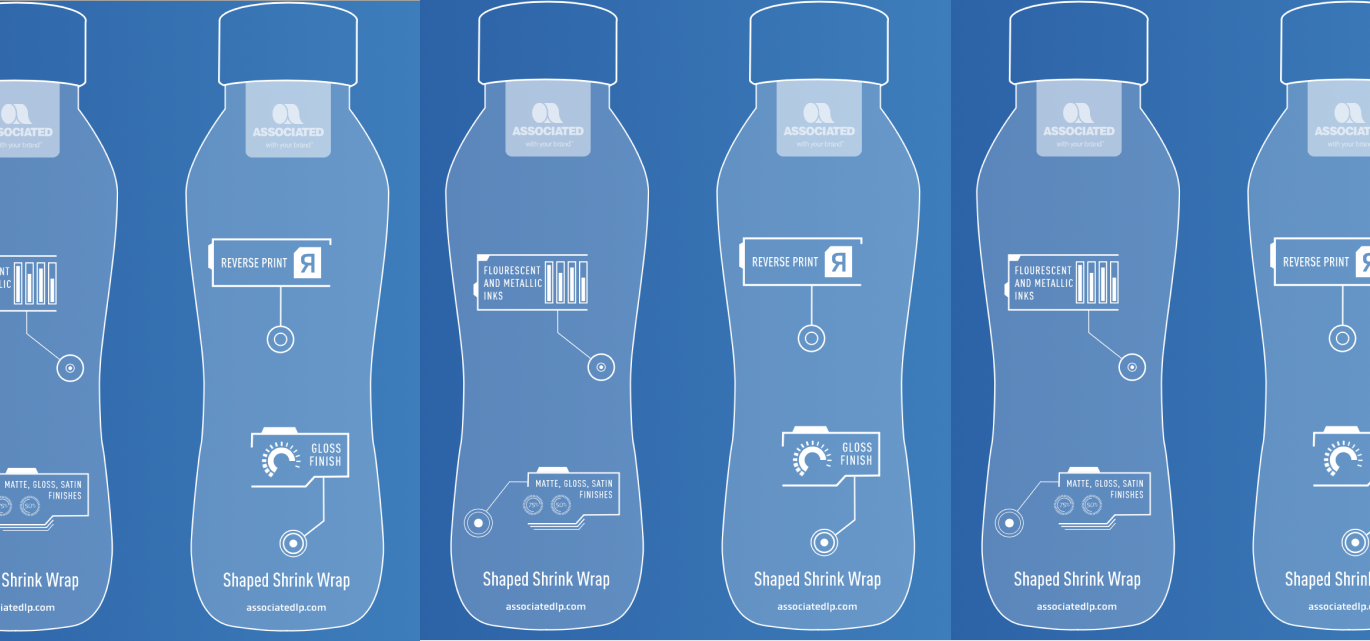

Shrink sleeves have become a popular packaging choice for products across many industries, from pharmaceuticals and nutraceuticals to food and beverage. Not only do they offer an opportunity for 360-degree branding, but they can also keep your product intact with high barrier properties. So, when creating a shrink sleeve, where should you begin?

Here are a few questions to use as starting points when creating a new shrink sleeve:

What product will you be packaging?

It's essential to know the exact product you're looking to package for many reasons:

What type of container will you be using?

It's imperative to get a sample of the container you’ll be using or a CAD drawing so that the dimensions used to create the initial art proof is 100% accurate. Shrink sleeves require distortion technology to ensure that the art looks perfect after the sleeve has been shrunk onto the container. If the art is even slightly off, the packaging can look distorted. At Associated, we use cutting-edge distortion management technology to achieve accurate art on your shrink sleeve.

How time-sensitive is your project?

Given the distortion needed for art, shrink sleeve projects can take longer than other products because of the necessary back-and-forth before the art is sent to production. Although production and the application itself can be completed relatively quickly, trialling is imperative for shrink sleeves.

What special features are you looking for?

Shrink sleeves can offer a range of finishes, including vertical perforation. This allows for quick removal by the end-user, which means that the container you use can be recycled easily, which is a great feature for customers who value sustainability.

How advanced is your design?

If you have an intricate design or your shrink sleeves will be used for products with many scents or variations, it might be better suited to be printed digitally. At Associated, we can print both digitally and with flexographic printing; you can find out more here.

For more information, reach out to one of our specialists here or request a quote online today!

Businesses across diverse industries choose Associated Labels & Packaging to expand their product lines.